Understanding the Basics of Circuit Protection

Circuit protection might seem like a secondary consideration in electronic design, but in reality, it’s one of the most critical aspects of creating reliable, long-lasting devices. Over my decade working with electronics manufacturers, I’ve seen how proper protection can mean the difference between a product that lasts for years and one that fails prematurely.

Active vs Passive Protection: Key Differences

Passive protection components operate without external control, responding automatically to circuit conditions. These include familiar devices like fuses, metal oxide varistors (MOVs), and transient voltage suppression (TVS) diodes. What makes passive components particularly valuable is their simplicity and reliability – they don’t require additional power sources or complex control circuits.

Active protection components, on the other hand, require external power and often incorporate sophisticated monitoring and control systems. These include overcurrent protection ICs, thermal management circuits, and voltage supervisors. The advantage here is precision – active components can respond more accurately to specific conditions and often provide protection without permanent damage to the circuit.

Selecting the Right Protection Strategy

Choosing between active and passive protection isn’t an either-or decision. The most effective designs typically incorporate both approaches. For instance, a power supply might use a fuse as final protection against catastrophic failure while employing active current limiting for normal operation variations.

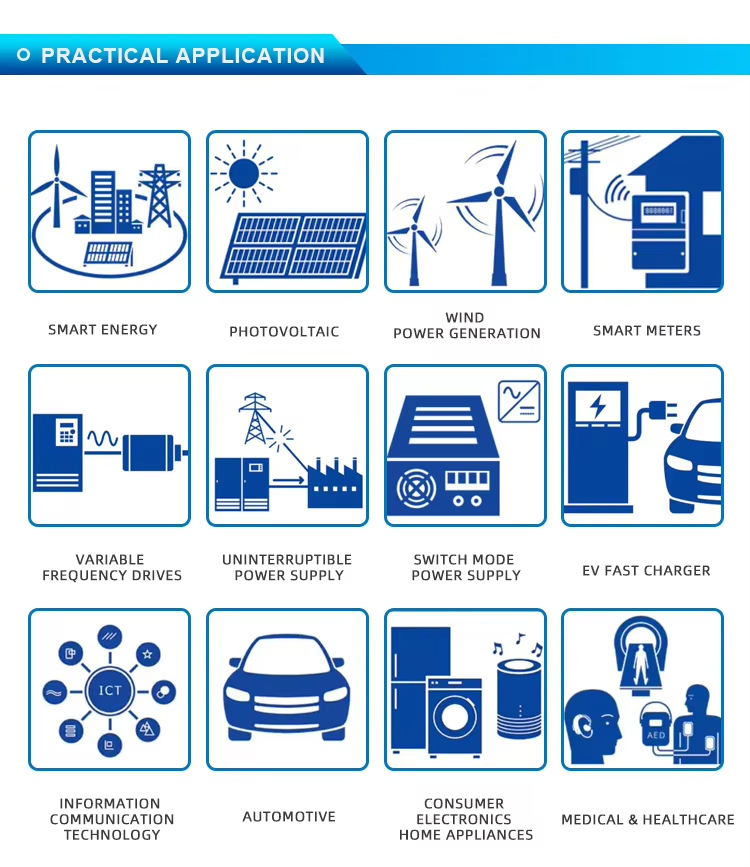

Several factors influence this decision: cost constraints, space limitations, reliability requirements, and the specific threats the circuit might face. In automotive electronics, for example, protection against load dump transients is crucial, while industrial controls need robust protection against electromagnetic interference.

Key Considerations for Protection Selection

- Response Time: How quickly does the protection need to react to a fault?

- Reset Capability: Does the protection need to automatically reset or is manual intervention acceptable?

- Cost vs Performance: What’s the budget for protection components?

- Space Constraints: How much board space is available for protection devices?

- Environmental Factors: Will the device operate in extreme temperatures or harsh conditions?

Emerging Trends in Circuit Protection

The field of circuit protection continues to evolve with new technologies and approaches. Smart protection ICs now incorporate diagnostics and communication capabilities, allowing systems to monitor their own protection status and even predict potential failures. This represents a significant shift from reactive protection to proactive system health management.

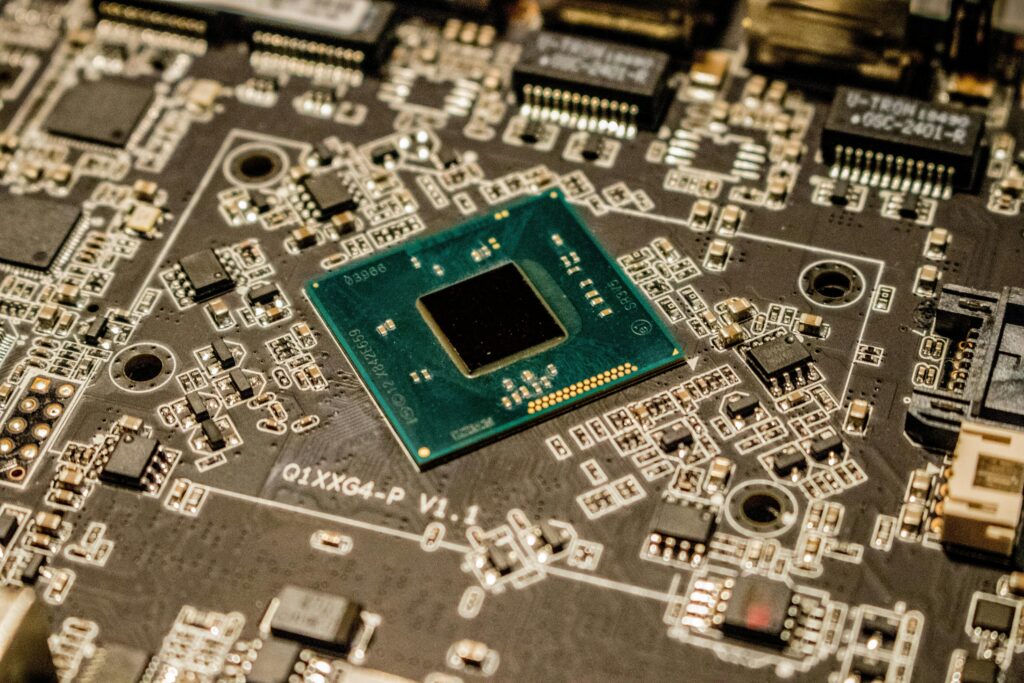

Another interesting development is the integration of protection directly into semiconductor devices. Many modern ICs now include built-in overvoltage, overcurrent, and thermal protection, reducing the need for external components while improving overall system reliability.

“The future of circuit protection lies in intelligent, integrated solutions that not only protect but also communicate their status and predict potential failures before they occur.”

Implementation Best Practices

When implementing circuit protection, it’s essential to consider the entire system rather than individual components. A holistic approach ensures that protection devices work together effectively without creating new failure modes. Testing under realistic conditions is crucial – what works in a controlled lab environment might not perform as expected in the field.

Documentation is another often-overlooked aspect. Clear documentation of protection strategies helps with troubleshooting and future design iterations. It’s also valuable for regulatory compliance and certification processes.