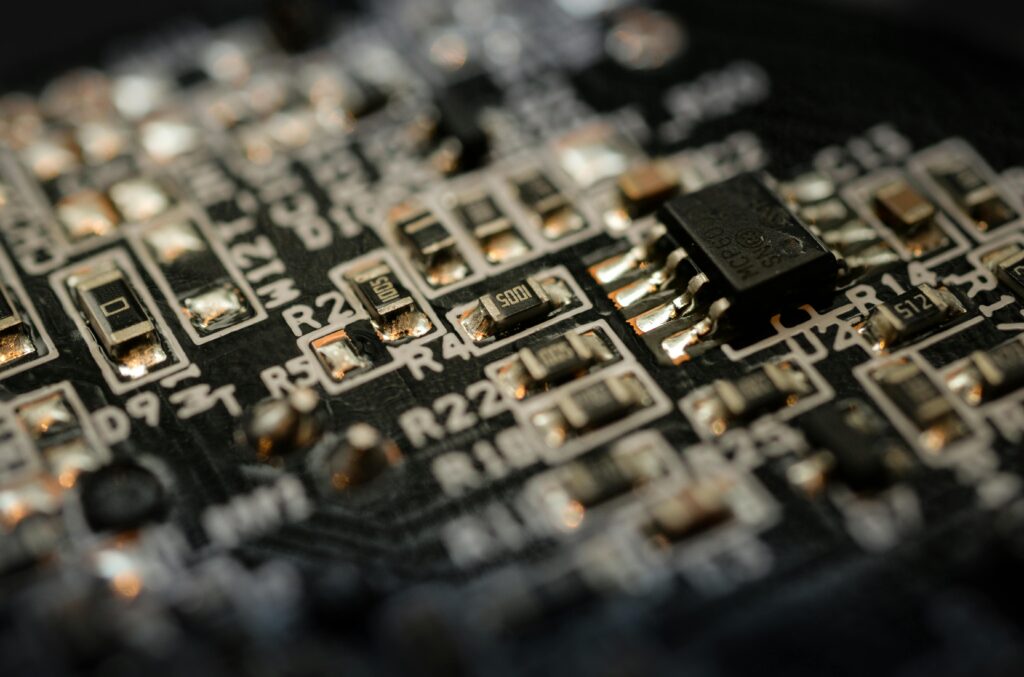

The Changing Landscape of Electronics Sourcing

The global electronics supply chain has undergone dramatic changes in recent years, presenting both challenges and opportunities for businesses of all sizes. From my experience working with manufacturers and suppliers across Asia, Europe, and North America, I’ve observed how adaptability and strategic thinking have become more important than ever in component sourcing.

Key Supply Chain Challenges

The semiconductor shortage that began in 2020 revealed vulnerabilities in highly optimized supply chains. Automotive manufacturers, consumer electronics companies, and industrial equipment producers all faced significant disruptions despite sophisticated supply chain management systems. The crisis demonstrated that efficiency-focused models work well in stable conditions but lack resilience during systemic shocks.

Geopolitical factors have added another layer of complexity. Trade tensions, tariffs, and regional conflicts have forced companies to reevaluate their sourcing strategies and develop contingency plans for various scenarios. This new reality requires a more nuanced approach to supplier relationships and risk management.

Common Supply Chain Disruptions

Electronic component manufacturers face numerous potential disruptions:

- Raw Material Shortages: Limited availability of silicon, rare earth elements, and other essential materials

- Manufacturing Capacity Constraints: Limited fab capacity for semiconductor production

- Logistical Challenges: Port congestion, shipping delays, and transportation costs

- Quality Control Issues: Counterfeit components and quality variations

- Regulatory Changes: Export controls, environmental regulations, and compliance requirements

Strategies for Building Resilient Supply Chains

Diversification has emerged as a critical strategy for building resilient supply chains. This involves not just multiple suppliers but also geographic diversity. Companies that maintained relationships with suppliers across different continents were better positioned to navigate regional disruptions and allocate resources effectively.

Inventory management strategies have also evolved. While just-in-time approaches minimize carrying costs, many companies are now adopting hybrid models that maintain strategic reserves of critical components. This “just-in-case” approach provides crucial insurance against supply disruptions, even if it increases short-term costs.

Supplier Relationship Management

Building strong relationships with suppliers has become more important than ever. Companies that treat suppliers as strategic partners rather than transactional vendors tend to fare better during shortages. Key elements of effective supplier relationship management include:

- Transparent communication about forecasts and requirements

- Fair pricing and payment terms

- Collaborative problem-solving approaches

- Long-term commitment and loyalty

Future Trends in Electronics Sourcing

Nearshoring and regionalization are gaining momentum as companies seek to reduce dependence on distant suppliers. While complete localization is rarely practical for complex electronics, strategic regional sourcing can provide important risk mitigation benefits while maintaining cost competitiveness.

Digital transformation continues to reshape supply chain management. Advanced analytics, IoT tracking, and blockchain technologies provide unprecedented visibility from raw materials to finished products. This enhanced transparency allows companies to identify potential disruptions earlier and respond more effectively to changing conditions.

“The most successful companies in the coming decade will be those that build agile, transparent supply chains capable of adapting to rapidly changing global conditions.”